Removing sticky droplets and making super repellent surfaces

Super-repellent surfaces lose their repellent properties when condensation occurs, either under low temperatures or high humidity conditions. A new surface has been developed, combining pyramidal microstructures with a nano-sized roughness on top, that maintains its super-repellent properties at all conditions.

Lotus leaves show the amazing self-cleaning property that at low inclinations angles millimetre-sized droplets can roll easily, collecting dust from the leaf. This is why the lotus leaves remain clean even when they grow in dirty waters. However, if the temperature of the surface of the leaf is reduced and small droplets condense on the surface, this water-repellent property is lost, and the droplets get attached to the leaf hindering its the self-cleaning property. This loss of super-repellent properties during condensation is observed for many different types of surfaces.

Many scientific and industrial applications require to maintain the self-cleaning property even when condensation is formed on the surface, for example for harvesting water in the deserted areas or for keeping the windows clean and without ice at home. Also, condensation plays a major role in the petrochemical and power generation industries. However, how to achieve the super-repellent surface when condensation occurs has been a major puzzle.

Working on the nano level

As small droplets are formed inside the microstructures of the surface due to condensation of vapor in the environment, a droplet deposited on the surface will get attached to the liquid already present within the structures. The deposited droplet will lose mobility and it will remain attached to the surface. Instead, if the small droplets forming within the microstructures can be removed from the surface, then the super-repellent property can be maintained. But how? This has remained as a major question.

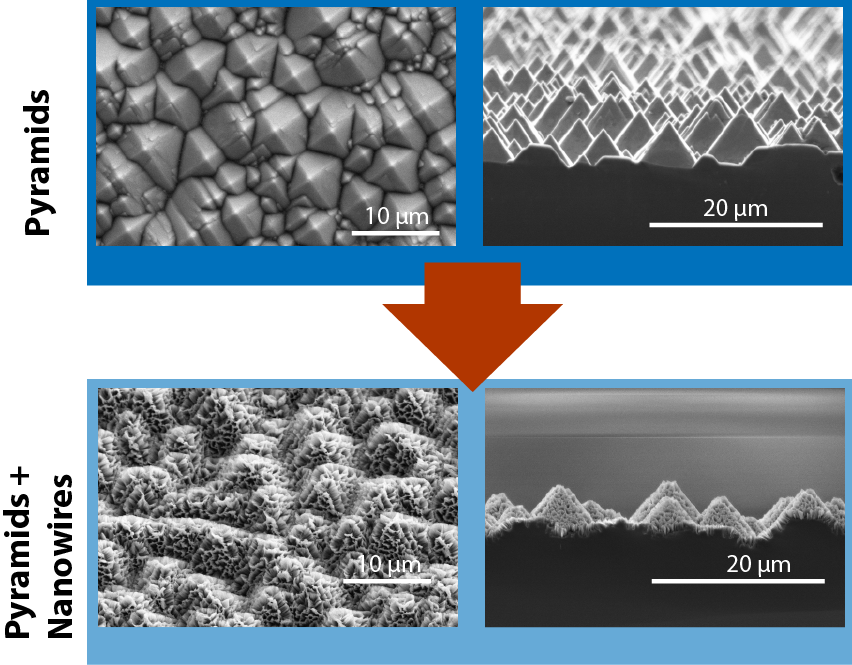

In this work a new surface was designed capable of avoiding the accumulation of small droplets during condensation. The surface consists of micro-sized pyramids with a nano-scale roughness added on top.

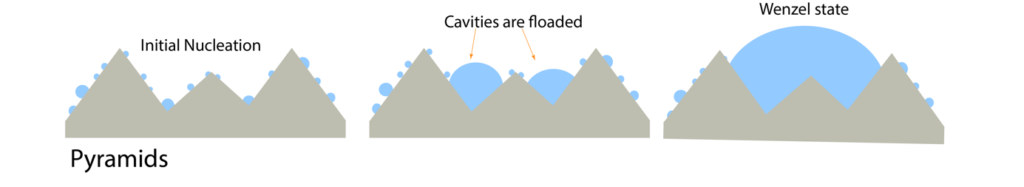

In a surface with only pyramidal structures the condensation of small droplets floods the cavities. Thus, a deposited droplet gets attached to the liquid already present on the surface and the droplet cannot move.

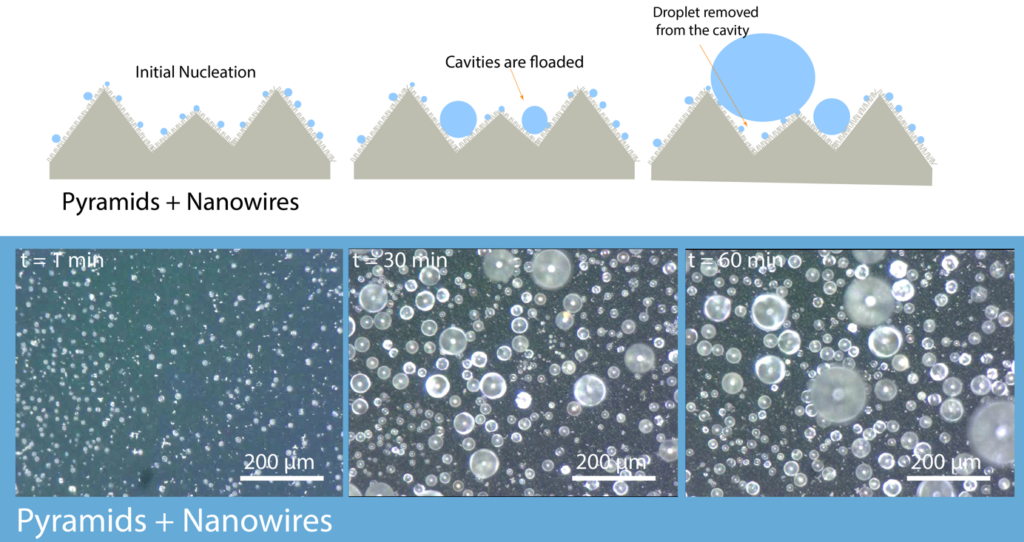

However, if a nanostructure is added on top of the pyramidal structures, the small droplets that appear due to condensation are repelled by the nano-sized structures in the cavities. When a new droplet is deposited on the surface, the droplet is able to absorb the small droplets already exiting below, pulling them up and cleaning the cavities. Thus, the droplet remains at the top of the structures and can move easily on the surface.

Possible to achieve super repellent condition

This surface has shown the possibility of achieving a super-repellent condition even when condensation is occurring on the surface. The picture shows the condensation of droplets on the surface where it is possible to observe that the droplets remain on top of the structures. The same type of experiments were performed with cylindrical pillars instead of pyramids, but the liquid was not easily removed from within the cylindrical structures. Pyramids help provide the necessary upward force for droplets to migrate above the structures, while the nano-roughness on the pyramids detaches the small droplets formed by condensation.

The details of the study are available in this publication:

Water-Repellent Surfaces Consisting of Nanowires on Micropyramidal Structures. ACS Appl. Nano Mater. 2019, 2, 12, 7696-7704 https://pubs.acs.org/doi/abs/10.1021/acsanm.9b01767

Wenjing Zhang

Wenjing Zhang is a PhD candidate at NTNU - Department of Energy and Process Engineering. She is affiliated with the Thermal Two-Phase Flow Laboratory (ThTPFLab). The surface fabrication and characterization has been done at the NTNU Nanolab.

Wenjing Zhang

Search

Søk

Categories

- Arctic Research

- Arkitektur

- Bærekraft

- Bioingeniørfag

- Biologi

- Biology

- Biomedical Laboratory Science

- Biotechnology

- Bioteknologi

- Chemical Engineering

- Chemistry

- Climate

- Computer Science

- Datateknologi

- Digital

- Elektronikk

- Energi

- Energi

- Energy

- Engineering

- Engineering

- Environment

- Food Science

- Forskning

- Fysikk

- Fysikk

- Havbruk

- Informasjonsteknologi

- Informasjonsteknologi

- Ingeniørvitenskap

- Kjemi

- Kjemisk prosessteknologi

- Kjemisk prosessteknologi

- Kreftbehandling

- Kybernetikk

- Marine Technology

- Materialer

- Materials Science

- Materialteknologi

- Matvitenskap

- Meninger

- Miljø

- Min ph.d.

- My PhD

- My PhD

- My postdoc

- Nanotechnology

- Nanoteknologi

- Ocean

- Oil and gas

- Physics

- Research

- Simulering og visualisering

- Spør en forsker

- Studentliv

- Sustainability

- Ukategorisert

- Universitetsliv

- University Life

Kategorier

- Arctic Research

- Arkitektur

- Bærekraft

- Bioingeniørfag

- Biologi

- Biology

- Biomedical Laboratory Science

- Biotechnology

- Bioteknologi

- Chemical Engineering

- Chemistry

- Climate

- Computer Science

- Datateknologi

- Digital

- Elektronikk

- Energi

- Energi

- Energy

- Engineering

- Engineering

- Environment

- Food Science

- Forskning

- Fysikk

- Fysikk

- Havbruk

- Informasjonsteknologi

- Informasjonsteknologi

- Ingeniørvitenskap

- Kjemi

- Kjemisk prosessteknologi

- Kjemisk prosessteknologi

- Kreftbehandling

- Kybernetikk

- Marine Technology

- Materialer

- Materials Science

- Materialteknologi

- Matvitenskap

- Meninger

- Miljø

- Min ph.d.

- My PhD

- My PhD

- My postdoc

- Nanotechnology

- Nanoteknologi

- Ocean

- Oil and gas

- Physics

- Research

- Simulering og visualisering

- Spør en forsker

- Studentliv

- Sustainability

- Ukategorisert

- Universitetsliv

- University Life