Inventor of the NTNU Corona test method: Q&A with Sulalit Bandyopadhyay

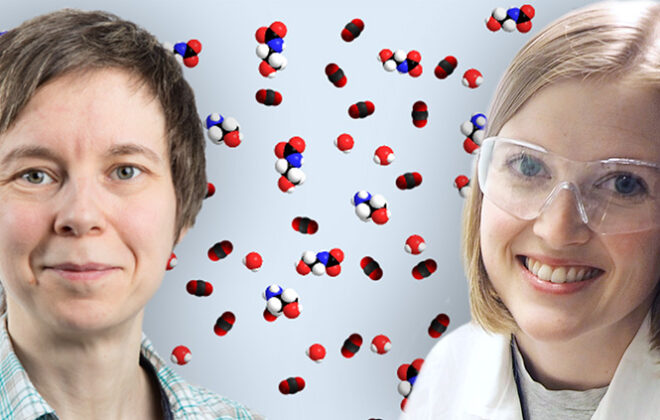

Sulalit Bandyopadhyay and his team invented the NTNU Corona test method in collaboration with Magnar Bjørås’ team at the Department fo Clinical and Molecular Medicine. The test is now being widely used, not only nationally but also abroad. Sulalit is an associate professor of particle engineering and hydrometallurgy at the Department of Chemical Engineering at NTNU.

What is your role at NTNU?

My role is split between research, teaching, and administration.

On the research side I look at nanoparticles, controlling their properties and making them for different applications: from biomedicine – like drug delivery and diagnostics – to water management, and oil and gas. We are interested in understanding how these particles grow and how we can control their shapes.

The hydrometallurgy part is where I’m looking at recycling materials, mostly batteries, for example, lithium ion batteries from electric cars.

Your work led you to get involved with the pandemic response last year by making coronavirus tests that have been used in several countries. How did that come about?

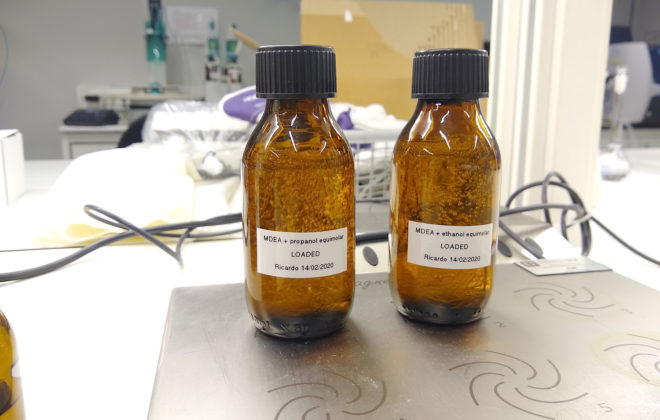

In March there was a shortage of test kits at the hospital and researchers at NTNU were looking for ways to help. My lab got a late night email from a colleague who knew we were working on magnetic particles in suspension, and we started work on the tests the next morning. In the first few days we were basically making some small batches and testing them, and within five days we had our protocols validated – the particles were working.

Then we had the biggest challenge: upscaling. Nanotechnology is very good in small volumes and small scales, but the moment you start to do it on a larger scale you end up with different problems. The project made me overcome my fear of upscaling. From making kits for a thousand tests we were able to immediately go up to 150,000 a week.

What are you working on next?

We want to use the COVID-19 test particles for other kinds of virus diagnosis. At the same time, with our chemical engineering skills, we are looking at trying to make them continuous processes, instead of one-pot reactions.

What was your last paper about?

This one was about tracking how water flows. Our contribution was making the hydrological tracer particles: iron oxide nanoparticles, loaded with synthetic DNA and encapsulated in a silica shell. They are very similar to the COVID-19 test particles, but those don’t have the DNA.

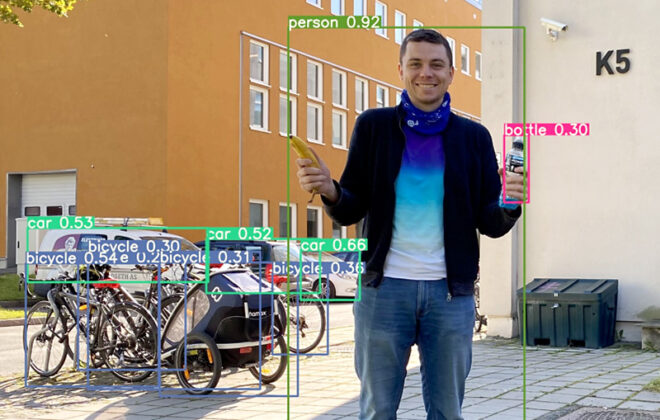

Each particle is loaded with a different type of DNA, so we can see which particles have moved and which particles are still trapped, just by reading the code. The movement of the particles can then tell us how the water is flowing in the environment.

What opportunities do you see to work with others?

Our work is very interdisciplinary, and that’s the reason we can never function by ourselves completely – we always need good and strong collaborators. We work with many other groups across NTNU, other universities around the world, and with industry too.

Within NTNU, for example, we have very active collaborations with the Departments of Biophysics, Chemistry, Clinical and Molecular Medicine, Biotechnology, Civil and Environmental Engineering and many others . Externally our strongest collaborator is TU Delft in the Netherlands who we work with on the hydrological tracers, and several universities in Europe, USA, Malaysia, Indonesia, India and Pakistan.

What do you most enjoy about your work?

Summer is a time of the year where I am able to see the whole picture of what we have been doing over the past few weeks and months. After all the hard work, all the commitments, sickness, instrument failures, no results, strong reviews, strong comments – the list is very long. But after everything, we can see progress. That’s very important.

What do you see as the biggest challenge in your research?

What I would like to achieve is either diagnosing a very difficult-to-diagnose disease, or making a cure for one, using nanotechnology.

Alzheimer’s disease, for example, is something we would like to focus on in the future. It doesn’t have a treatment yet, and we are proposing the use of certain kinds of nanoparticles to halt the progression of the disease. This is something maybe 5-10 years down the line, we are not there yet. The big challenge will come in taking this from the lab to the clinic.

What motivates you?

I never want to stop having the urge to invent. You can get so bogged down with your regular work that you forget why you chose this profession. For me, I would really like to continue working in the lab, doing things myself practically – not only relying on students to do that work.

What do you do in your spare time?

I love to play badminton and cricket. I sat on the Norwegian Cricket Federation steering board for the last two years. We have 55 teams in Norway and there are seven clubs in Trondheim. We built the cricket ground in Trondheim five years ago with help from others. There’s a lot to do in cricket here.

Kelly Oakes

Kelly Oakes is writing science articles for NTNU Nano. She is a freelance writer and editor living in London.

Tags In

Search

Søk

Categories

- Arctic Research

- Arkitektur

- Bærekraft

- Bioingeniørfag

- Biologi

- Biology

- Biomedical Laboratory Science

- Biotechnology

- Bioteknologi

- Chemical Engineering

- Chemistry

- Climate

- Computer Science

- Datateknologi

- Digital

- Elektronikk

- Energi

- Energi

- Energy

- Engineering

- Engineering

- Environment

- Food Science

- Forskning

- Fysikk

- Fysikk

- Havbruk

- Informasjonsteknologi

- Informasjonsteknologi

- Ingeniørvitenskap

- Kjemi

- Kjemisk prosessteknologi

- Kjemisk prosessteknologi

- Kreftbehandling

- Kybernetikk

- Marine Technology

- Materialer

- Materials Science

- Materialteknologi

- Matvitenskap

- Meninger

- Miljø

- Min ph.d.

- My PhD

- My PhD

- My postdoc

- Nanotechnology

- Nanoteknologi

- Ocean

- Oil and gas

- Physics

- Research

- Simulering og visualisering

- Spør en forsker

- Studentliv

- Sustainability

- Ukategorisert

- Universitetsliv

- University Life

Kategorier

- Arctic Research

- Arkitektur

- Bærekraft

- Bioingeniørfag

- Biologi

- Biology

- Biomedical Laboratory Science

- Biotechnology

- Bioteknologi

- Chemical Engineering

- Chemistry

- Climate

- Computer Science

- Datateknologi

- Digital

- Elektronikk

- Energi

- Energi

- Energy

- Engineering

- Engineering

- Environment

- Food Science

- Forskning

- Fysikk

- Fysikk

- Havbruk

- Informasjonsteknologi

- Informasjonsteknologi

- Ingeniørvitenskap

- Kjemi

- Kjemisk prosessteknologi

- Kjemisk prosessteknologi

- Kreftbehandling

- Kybernetikk

- Marine Technology

- Materialer

- Materials Science

- Materialteknologi

- Matvitenskap

- Meninger

- Miljø

- Min ph.d.

- My PhD

- My PhD

- My postdoc

- Nanotechnology

- Nanoteknologi

- Ocean

- Oil and gas

- Physics

- Research

- Simulering og visualisering

- Spør en forsker

- Studentliv

- Sustainability

- Ukategorisert

- Universitetsliv

- University Life