Library functions.

ThermoML, a software developed

using extensible mark-up language (XML), was identi-

fied as the most appropriate tool for preserving exper-

imentally verified data. ThermoML is adopted as IUPAC

Standard for Storage and Exchange of Experimental

Thermophysical and Thermochemical Property Data.

ThermoML is designed to store and transport data in

both machine and human readable format. If this tool

answers the needs expressed by SFI members remains

to be verified by user acceptance.

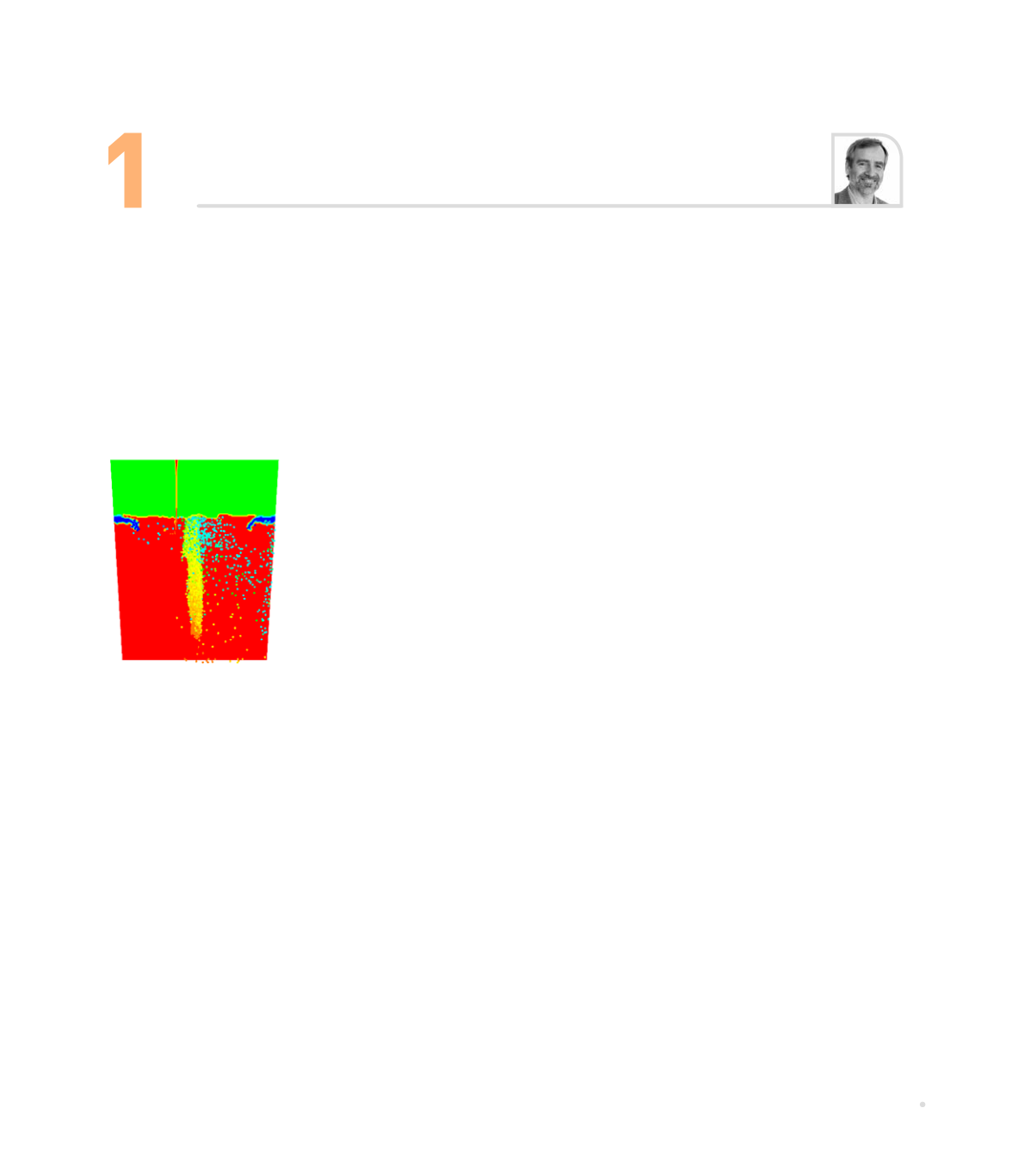

Methodology coupling of

modelling tools.

Silicon re-

fining was used to demon-

strate coupling between

detailed computational fluid

dynamic (CFD) modelling

and pragmatic modelling in

spreadsheet and MatLab.

Key elements in the model

require heavy computational

power and takes a long time

to calculate. Such key ele-

ments may be the surface of bubbles and droplets, which

are extracted over short time intervals by computational

fluid dynamics (CFD), before being applied in computing

the complete refining cycle with moderate use of calcu-

lation time The work will be presented in the CFD 2017

(12th International Conference on Computational Fluid

Dynamics in the Oil & Gas, Metallurgical and Process

Industries) in Trondheim May 30 to June 1.

Modelling the SiMn reduction processes.

As a part of

RD2, postdoc Sebastien Letout is working on model

expressions to enhance the understanding of kinetic

processes within the SiMn pilot scale furnace. In the

current approach, OpenFOAM (Open Field Operator And

Manipulation), a free and open code, is used as an alter-

native to expensive commercial software for computa-

tional fluid dynamics. Modelling the smelting operations

are complex and not straightforward, as most of the local

kinetics in the furnace can not be observed in situ, and

results from excavations after cooling the furnace may

be ambiguous. Written documentation of similar pro-

cesses and observations, and species analyses after ex-

cavations, are used to develop numerical simulations to

test the hypothesis formulated on the internal behaviour

of the furnace. A first stage is to understand phenomena

taking place inside the coke bed, in the dripping zone

where the slag flows around the carbon particles before

accumulating at the bottom of the furnace. A paper will

be presented at the CFD 2017 conference in Trondheim.

Road map.

The road map process for RD1 finished in

2016. The main objectives for RD1 are slightly modified

based on the discussions:

• Data Curation (libraries) - Verify systems suitable

for collecting existing and new data in easily

accessible and user-friendly libraries while still

maintaining the need for proper and trackable

verification of data and data uncertainties.

• Modelling - Establish methodology to verify

generic modelling frameworks for coupled

scientific computing, using readily available

software tools with sufficient flexibility to

establish a platform for innovations in the

industry.

Many options for RD1 involvement with the other

Research Domains are reported in the Road map

document.

Europeanmaterialsmodelling council (EMMC).

Teknova

is following up on this network. In the long run, this may

be an gateway to participation in European projects.

Modelling alumina dissolution.

A workshop was ar-

ranged in December 2016 to initiate activities related to

alumina feeding and dissolution in aluminium electrol-

ysis bath, starting in 2017. There will be two PhD can-

didates on modelling, one at the University of Oxford in

cooperation with Teknova and one at NTNU. One associ-

ated PhD will focus on electrochemical activities related

to alumina concentration in the bath.

Fundamentals and Modelling Tools (RD1)

by Senior Research Scientist Arne Petter Ratvik

15

Highlights of 2016 from the Research Domains