Power to the Modeller

Modelling chemical and biological processes is actually a multi-scale as well as a multi-disciplinary problem that requires expert knowledge from different scientific domains. This circumstance often turns model design into a time-consuming and elaborate task. Providing the modeller with an extensively automated modelling suite equipped with multi-disciplinary expert knowledge is thus a critical undertaking: Allow us to introduce the modelling suite ProMo to you.

First things first: Our understanding of the world is rather limited. For example, although we know the basics of weather conditions and molecules, we are still not able to completely describe their complex inner workings or accurately predict their behaviours. We thus have to design mathematical constructs that mimic the behaviour of complex physical objects. These mathematical constructs are what we call models and they allow for tampering and testing to predict the real-world behaviour of the modelled object.

In process engineering, large parts of design, optimisation and control centre on models, with simulation being the primary target. Experimental studies may be the conventional alternative but they are expensive, time-consuming and often not viable in all operational areas or even reliable for the exploration and testing of differing process scales. Numerical simulations are done in computers and as such not limited by physical constraints. They thus allow for the exploration of physical regions that are commonly not accessible by experimental work.

The fast development of computing in recent decades rapidly increases the capabilities of process simulation, thereby enabling the simulation of more and more complex models. Models are thus in the centre of process systems engineering, with a high demand placed on the modellers. The increasing need for modelling prompts an increasing interest in more effective model generation processes that incorporate the various expert’s knowledge.

The elephant in the model design’s room

With models being at the top end of the overall assessment process, correctness and completeness of the model equations are of the highest priority in modelling. Since the processes we observe are actually an ensemble of various processes on a much smaller scale, the model design has thus to incorporate multiple scales for the sake of accuracy: The macroscopic process scale and the microscopic scales of the process’ elements as well as all the materials being processed, just to name the major ones. Multi-scale modelling requires expert knowledge from several disciplines like mathematics, physics, biology and chemistry, as well as process control and engineering. This holds true especially in the biorefinery community: Modern biorefinery concepts have to utilise a vast amount of scientific disciplines for reliable scale-up studies, effective process control implementations and accurate bottleneck-pinpointing in order to get the most out of any feedstock in competitive pricing ranges. One modeller cannot be an expert in all of these topics and, more often than not, communication between experts of different scientific fields appears to be cumbersome. Although large companies can afford to establish multi-disciplinary expert groups, that is often not feasible for smaller businesses and individual modeller. Capturing expert knowledge in a modelling suite can thus open up new prospects for many projects and may have the effect of building bridges between different disciplines and people.

Just as much as modern research and development efforts have to be joint ventures of multiple, very different scientific disciplines, an accurate model design will never be achieved with only the expertise of one scientific domain.

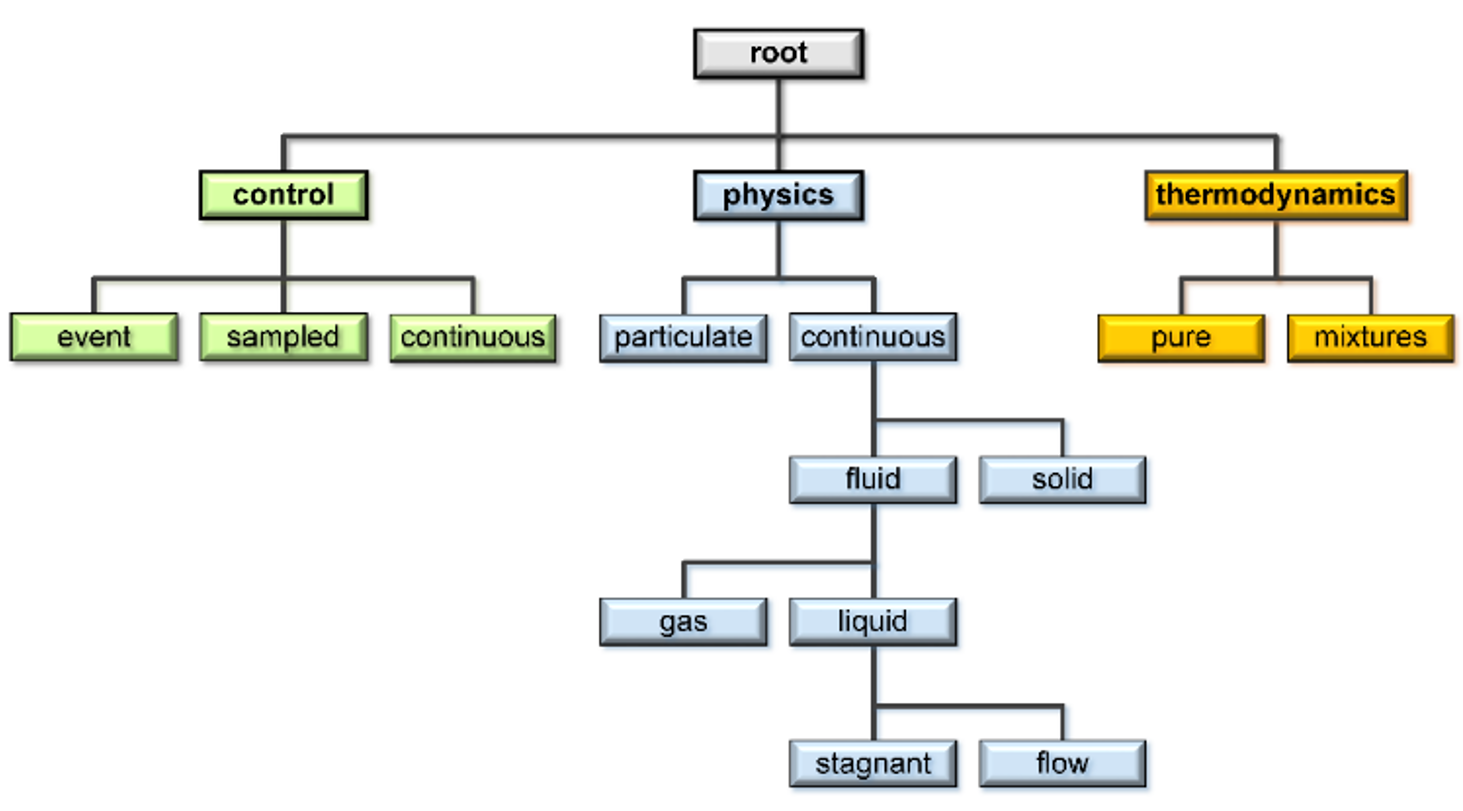

The modelling suite ProMo is our response to that problem as it is particularly the multi-disciplinary aspect that ProMo implements, being built on the foundation of discipline-specific ontologies. The term ontology encompasses the entirety of fundamental concepts, definitions and relations taken from the application-specific scientific roots. Ontologies are a means of abstraction and concentrating information, promoting a more systematic approach to model design [1]. They define the discipline’s terminology, like the definitions put at the beginning of legal contracts. Ontologies can thereby serve as model design instructions, thus not just as guidelines, but as a set of hard regulations that must be adhered to. As depicted in Figure 1, this knowledge’s essence of a given discipline can further be structured hierarchically into sub-disciplines, resulting in a tree of ontologies where each branch in the tree inherits the parent paths completely [2]. The root contains the structural fundamentals for model design. Building on that root, the first level of the physics ontology contains it hard first principles such as the conservation principles of mass, energy and momentum, and geometry. Subsequently, the physics tree branches out, for example by splitting into concepts specific for fluids or solids.

Some similar forms of knowledge management were integrated into modelling software tools before, such as MODEL.LA [3], Ascend III [4], ModDev [5], ModKit [6] and Daedalus [7]. The ontology concept was introduced to the chemical engineering community particularly by the work of Marquardt’s group at the RWTH Aachen [8]. Since then it has proven its usefulness in terms of accelerating the modelling process itself and improving its quality as well as the communication between different scientific domains [9].

The objective of ProMo is, for example, to aid the modeller as a flexible, broadly applicable tool in rapid model design. According to that task, the ProMo concept differs in its approach from other projects by assembling a construction kit of fundamental modules without any predefined interactions between them.

Talking apples and oranges

Modelling approaches commonly fall into one of two classes: Sequential-modular or equation-oriented. Most flowsheeting packages are built on the first approach in which a process is solved by estimating each sequential step as an unit operation individually. Those tools are often easy-to-use thanks to their intuitive user interfaces with built-in debugging diagnostics. Although that is sufficient for simple balancing, optimisation and custom modelling capabilities are rather limited. In contrast, many equation-oriented packages are so complicated and user-unfriendly that it needs specialists to run them. However, they often make up for that with extensive custom modelling and optimisation capabilities since they are not limited by sequences of unit operations.

By utilising basic building blocks in a heavily automated modelling suite, the ProMo concept is different from both classes, ultimately combining their strengths while avoiding most of the respective drawbacks.

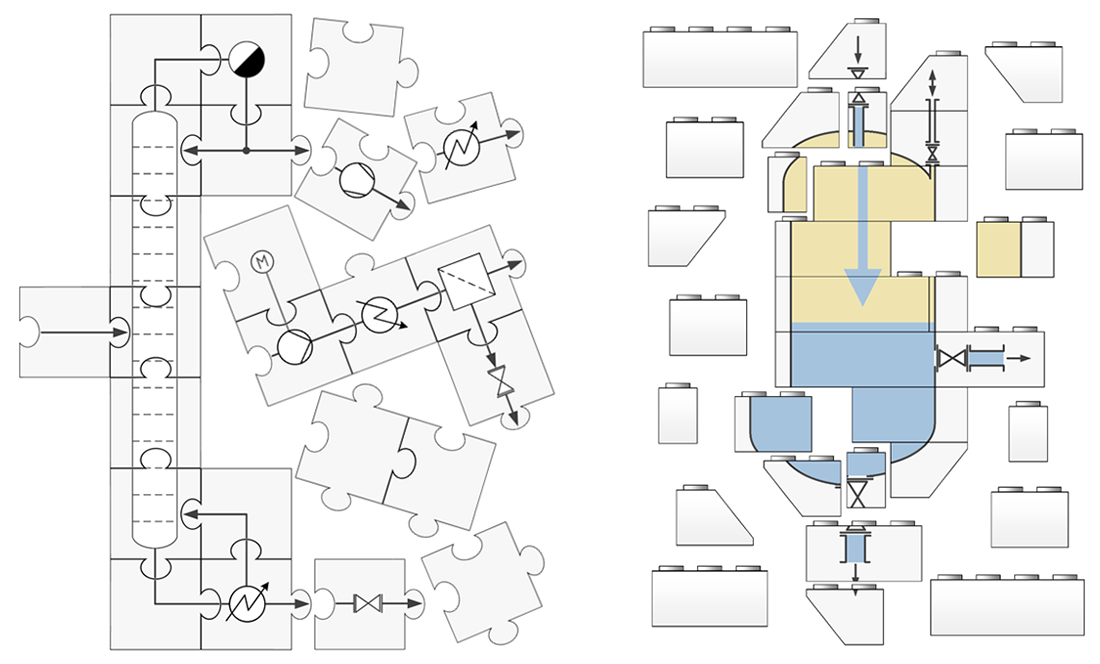

The idea of using basic components to assemble complex systems has been around for some time, as seen by flowsheeting packages. In those, unit operation models are pre-assembled and provided in libraries as building blocks for plant models. Each unit operation represents a physical unit such as a column or reactor as an input/output model with standardised connections. Commercial flowsheeting software tools like Aspen Plus® [10] are big players in the market mostly because of their extensive unit operation libraries, more than of their capabilities to solve numerical problems. Most of these packages are designed to solve steady-state mass and energy balances on a plant-wide scale. Quite obviously, even though this approach inherits the strengths of sequential-modular modelling, it is rather not sufficient for the design of dynamic, multi-scale models and that only a limited amount of networks can be constructed from this type of rather inflexible building blocks. The flowsheeting approach is thus similar to assembling puzzle pieces, as depicted in Figure 2 on the left side.

The ProMo approach similarly applies building blocks. However, our building blocks are a minimal set of fundamental entities without fixed connections. The complexity is constructed by assembling these fundamental entities into higher-level blocks, each of which consists of a network of entities and connections. Therefore, ProMo is close to building models out of LEGO® bricks, sketched in Figure 2 on the right, achieving the same freedom in custom modelling on different scales like complex plants [11], individual units [12] or even thin-film layers [13].

A venture enduring since the 80s

The ProMo concept grew out of earlier developments, which started in the 80s with the modelling of life-support systems for NASA [14, 15]. Flowsheeting software tools at that time were not applicable for this task, since those packages are based on unit operations, which are established individually in an input/output representation based on the derivatives of intensive quantities. Thereby, the flowsheeting approach often falls victim to typing errors and non-closed balances. Typing errors because each unit operation has to be coded individually and non-closed balances due to approximation-caused inaccuracies when integrating over intensive quantities. Therefore, model design in the Pathfinder project was based on a prototype computer-aided modelling tool that utilises graph representation in the form of topologies.

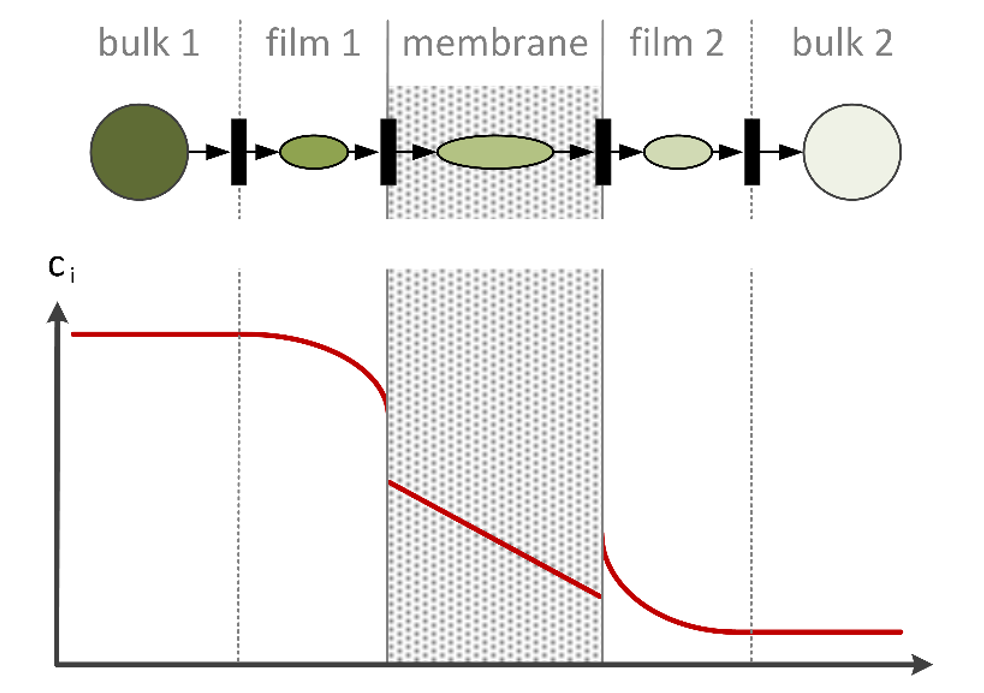

A topology abstracts a process by subdividing it into a network of self-contained volumes, which communicate with each other by means of flows of extensive quantities like mass, heat and work [16]. As exemplary shown in Figure 3, a process like a membrane filtration can be segmented into volumes (LEGO® bricks so to speak) associated with the respective structural parts of bulk volumes, film layers and membrane, thus depicting the diverse natures of each particular part. The abstract quality of topologies and the definition of the building blocks yields a minimal set of equations that are also left in their fundamental form, thus maximizing the reusability of the building blocks. The modeller is hence provided with an exhaustive model kit from which every model can be designed.

The experience and key findings of this former NASA project, together with enhancements and intensifications resulting from later research as well as PhD projects, led to further developments of the concept in subsequent years, generating four generations of computer-aided modelling tools. The 3rd generation of these ProMo precursors, a self-contained software package called Modeller, even found commercial application by Mobatec BV (Netherlands) in 2004 [17].

Common flowsheeting packages often fall victim to typing errors and non-closed balances – key issues that can easily be avoided by the ProMo approach.

Since its early days, the ProMo concept grew in its scope, namely by extending on the topics of automated code generators and ontologies. The current version of the ProMo modelling suite, developed in the group of Professor Heinz A. Preisig at NTNU, is built on a set of ontologies that define the mathematical context for the model construction for several disciplines generically, like physics, process control and thermodynamics. From that set of ontologies, the appropriate model equations are automatically selected and translated into executable simulation code [18]. Additionally, the software can cover multiple scales from the molecular level up to plant-wide considerations as well as several disciplines off-site conventional chemical engineering applications like, for example, demonstrated in the MoDeNa EU project with polymer foam formation and solidification [19, 20]

There’s a method to this software

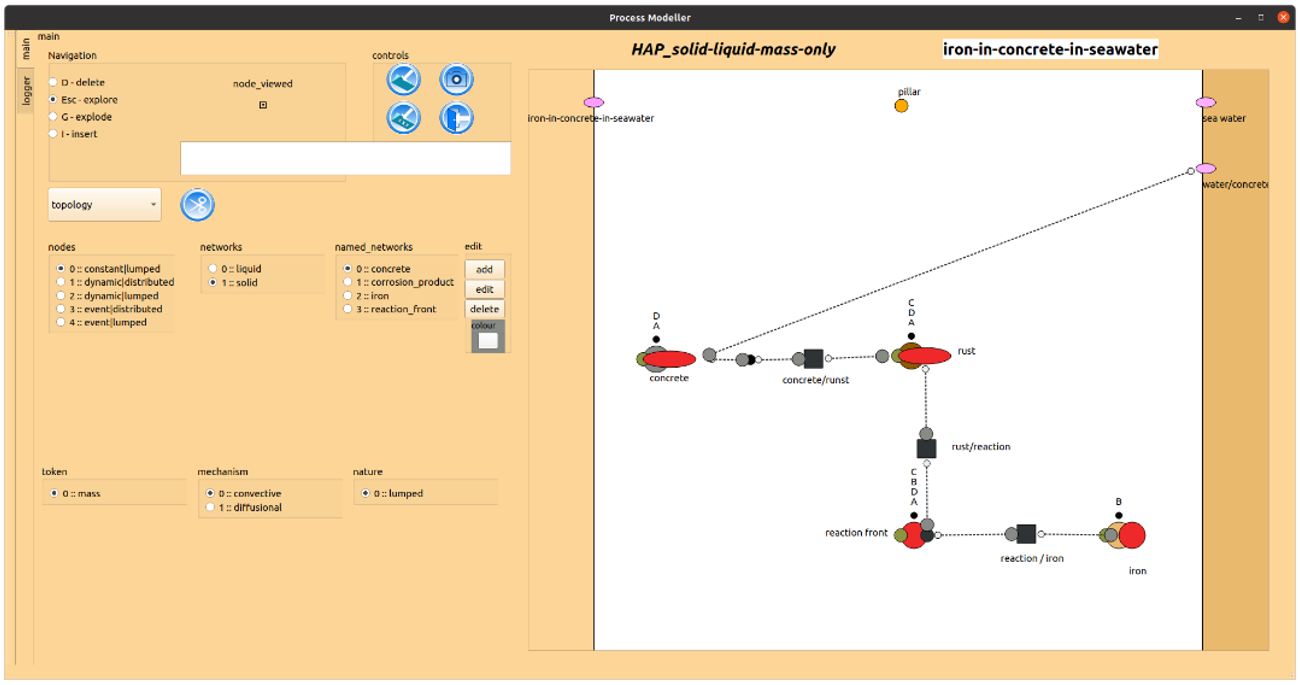

The ProMo software implements a step-wise approach for the model generation [21]: First, the process is abstracted in form of a topology that reflects the modeller’s view on the physical process. The graphical editor in Figure 4 provides the interface for the modeller and ensures that the model design is consistent with the context provided by the ontology tree deep-seated in ProMo. It is thus impossible to make mistakes that contradict the fundamental structure of any physical system [22].

Secondly, the equations that represent the behaviour of each element in the topology are selected from a discipline-specific part of the ontology provided by experts. The software automatically selects the appropriate equations for every part of the topology, thus enabling rapid as well as reliable model design. The last step is the generation of the actual code for simulation runs. The realisation of coded mathematical process models is usually a cumbersome and challenging task since the modeller needs to have expertise both in modelling and computer science. In ProMo, however, the assembled model is automatically written into executable program code in the desired output format like C++ and python™. Models constructed in this framework have the same code structure regardless of which scope: Industrial plants, colliding molecules or lab-scale fermenters, just to name a few. Therefore, all models can be processed by the same simulation and solver software tools. Furthermore, the code representing the individual model parts is centralised in a single block of code within ProMo, contrasting other software packages in which the mathematical behaviour of the overall process is distributed across the whole code with particular equations appearing multiple times.

Due to this approach, ProMo goes far and beyond common modelling tools by not only utilising the advantages of topologies and ontologies but also automating most of the time-consuming steps in model design.

Further along the road

After decades of concept refinement, enhancements and software iterations, one simple but visionary modelling approach from the 80s is about to conclude in the latest version of the ProMo modelling suite. However, such an undertaking has its challenges, not at least a social one: Any new approach is different from its predecessors and anything different has to work with or overcome the structures established by conventions. For the modeller, new tools have to provide functional but simple and self-explanatory interfaces. Preferably similar to what the modeller is already familiar with. Additionally, enabling the use of external programs and databases is necessary, especially in multi-scale modelling and simulation. ProMo already utilises existing ontologies, specifically the European Material Modelling Ontology EMMO for the physical parts. ProMo is though not limited to existing structures.

We plan to extend the ontology soon to the process control domain, techno-economic measurements, life-cycle analysis and other relevant subjects in modern research and development. ProMo will also be equipped with an initial model library in which common unit operations like distillation columns, reactors and membrane filtration units are available for the modeller as pre-assembled models. Custom models can be saved either in pieces or as a whole in the extended model library for their use in even more complex models. Thanks to previous work in projects like MoDeNa and current cooperations with partners like Smallmatek [23] from the material science domain and DBFZ [24] from the biorefinery community, ProMo will also be tailored to the needs of modelling problems usually not sufficiently addressed in commercial software tools.

The future looks bright: ProMo automates most of the cumbersome, time-consuming steps of model design, allowing the individual modeller to focus on the structural model design without being an expert in all aspects of physics, coding or numerics.

Therefore, we reason that ProMo has in the future the unique potential to vastly support modelling efforts in general and biorefinery modelling in particular by establishing easy-access custom modelling regardless of the modeller’s background.

We are constantly looking for new processes to test, demonstrate and expand the capabilities of ProMo. Thus, please do not hesitate to get in contact with us for any questions, comments or collaboration intents!

References

[1] H. A. Preisig, “Thinking Ontologies,” Computer Aided Chemical Engineering, vol. 31, pp. 1682-1686, 2012.

[2] H. A. Preisig, A. Elve and S. Karolius, “More power to the individual modeller using ontologies,” Computer Aided Chemical Engineering, vol. 46, pp. 1099-1104, 2019.

[3] G. Stephanopoulos, G. Henning and H. Leone, “MODEL.LA. A modeling language for process engineering—I. The formal framework,” Computers & chemical engineering, no. 14.8, pp. 813-846, 1990.

[4] P. C. Piela, T. G. Epperly, K. M. Westerberg and A. W. Westerberg, “ASCEND: An object-oriented computer environment for modeling and analysis: The modeling language,” Computers & chemical engineering, no. 15(1), pp. 53-72, 1991.

[5] A. K. Jensen and R. Gani, “A computer aided modeling system,” Comput. Chem. Eng., no. 23, pp. 673-678, 1999.

[6] R. Bogusch, B. Lohmann and W. Marquardt, “Computer-aided process modeling with modkit,” Comput. Chem. Eng., no. 25, pp. 963-995, 2001.

[7] J. R. Leal, A. Romanenko and L. O. Santos, “Daedalus modeling framework: building first-principle dynamic models,” Ind. Eng. Chem. Res., no. 56 (12), pp. 3332-3346, 2017.

[8] W. Marquardt, J. Morbach, A. Wiesner and A. Yang, OntoCAPE: A re-usable ontology for chemical process engineering, Springer Science & Business Media, 2009.

[9] H. A. Preisig, “A Multi-layered Ontology for Physical-Chemical-Biological Processes,” Computer Aided Chemical Engineering, vol. 29, pp. 101-105, 2011.

[10] aspentech, “Aspen Plus®,” [Online].

[11] R. Pujan, R. Nitzsche, J. Köchermann and H. A. Preisig, “Modelling Ontologies for Biorefinery Processes – A Case Study,” Computer Aided Chemical Engineering, vol. 48, pp. 1963-1968, 2020.

[12] R. Pujan and H. A. Preisig, “Systematic Modelling of Flow and Pressure Distribution in a Complex Tank,” Computer Aided Chemical Engineering, vol. 48, pp. 1945-1950, 2020.

[13] R. Pujan and H. A. Preisig, “Systematic Modelling of Transport Processes across Interfaces,” Proceedings of the 31st European Symposium on Computer Aided Chemical Engineering (ESCAPE), 2021.

[14] H. A. Preisig, “On the representation of life-support system models,” SAE Transactions, pp. 617-629, 1989.

[15] H. A. Preisig, T.-Y. Lee and F. Little, “A Prototype Computer-aided Modelling Tool for Life-Support System Models,” SAE Technical Paper, 1990.

[16] H. A. Preisig, “Visual Modelling,” Computer Aided Chemical Engineering, vol. 34, pp. 729-734, 2014.

[17] M. R. Westerweele, Five steps for building consistent dynamic process models and their implementation in the computer tool Modeller, NL: Eindhoven University of Technology, 2003.

[18] A. Elve and H. A. Preisig, “From ontology to executable program code,” Computers & Chemical Engineering, vol. 122, pp. 383-394, 2019.

[19] H. A. Preisig, “Promo-a Multi-disciplinary Process Modelling Suite,” Computer Aided Chemical Engineering, no. Vol. 48, pp. 571-576, 2020.

[20] Norwegian University of Science and Technology NTNU , “MoDeNa – Modelling of morphology Development of micro- and Nano Structures,” CORDIS (European Commission), 2016. [Online].

[21] H. A. Preisig, “Constructing and maintaining proper process models,” Computers & chemical engineering, vol. 34.9, pp. 1543-1555, 2010.

[22] H. A. Preisig and T. Haug-Warberg, “Ontology approach to model construction,” Proceedings of the 22nd European Symposium on Computer Aided Process Engineering (ESCAPE), 2012.

[23] Smallmatek – Small Materials and Technologies,Lda, “Smallmatek,” [Online].

[24] Deutsches Biomasseforschungszentrum gemeinnützige GmbH, “DBFZ,” [Online].

Robert Pujan

Robert Pujan is a PhD candidate at the Department of Chemical Engineering at NTNU specializing in Process Systems Engineering

Heinz A. Preistig

Heinz A. Preistig is a professor in Process Systems Engineering at the Department of Chemical Engineering at NTNU

Tags In

Search

Søk

Categories

- Arctic Research

- Arkitektur

- Bærekraft

- Bioingeniørfag

- Biologi

- Biology

- Biomedical Laboratory Science

- Biotechnology

- Bioteknologi

- Chemical Engineering

- Chemistry

- Climate

- Computer Science

- Datateknologi

- Digital

- Elektronikk

- Energi

- Energi

- Energy

- Engineering

- Engineering

- Environment

- Food Science

- Forskning

- Fysikk

- Fysikk

- Havbruk

- Informasjonsteknologi

- Informasjonsteknologi

- Ingeniørvitenskap

- Kjemi

- Kjemisk prosessteknologi

- Kjemisk prosessteknologi

- Kreftbehandling

- Kybernetikk

- Marine Technology

- Materialer

- Materials Science

- Materialteknologi

- Matvitenskap

- Meninger

- Miljø

- Min ph.d.

- My PhD

- My PhD

- My postdoc

- Nanotechnology

- Nanoteknologi

- Ocean

- Oil and gas

- Physics

- Research

- Simulering og visualisering

- Spør en forsker

- Studentliv

- Sustainability

- Ukategorisert

- Universitetsliv

- University Life

Kategorier

- Arctic Research

- Arkitektur

- Bærekraft

- Bioingeniørfag

- Biologi

- Biology

- Biomedical Laboratory Science

- Biotechnology

- Bioteknologi

- Chemical Engineering

- Chemistry

- Climate

- Computer Science

- Datateknologi

- Digital

- Elektronikk

- Energi

- Energi

- Energy

- Engineering

- Engineering

- Environment

- Food Science

- Forskning

- Fysikk

- Fysikk

- Havbruk

- Informasjonsteknologi

- Informasjonsteknologi

- Ingeniørvitenskap

- Kjemi

- Kjemisk prosessteknologi

- Kjemisk prosessteknologi

- Kreftbehandling

- Kybernetikk

- Marine Technology

- Materialer

- Materials Science

- Materialteknologi

- Matvitenskap

- Meninger

- Miljø

- Min ph.d.

- My PhD

- My PhD

- My postdoc

- Nanotechnology

- Nanoteknologi

- Ocean

- Oil and gas

- Physics

- Research

- Simulering og visualisering

- Spør en forsker

- Studentliv

- Sustainability

- Ukategorisert

- Universitetsliv

- University Life