Growing seafood on land – a more sustainable option towards food sustainability

The demand for seafood is rising like never before, and unsustainable fishing has depleted the oceans. Recirculating aquaculture systems (RAS) can present a sustainable solution by producing seafood in land-based systems with water treatment and reuse. At the heart of the RAS water treatment system is the nitrifying bioreactor. The bioreactor contains microbes that remove the ammonia produced by the fish, thus maintaining the ammonia concentration at safe levels for the fish.

Controlling salinity levels

Atlantic salmon are typically reared in freshwater RAS until they are seawater-adapted (smoltified), and then transferred to sea-cages for further growth and harvest. Several factors have led to an increasing interest in growing salmon to a larger size in RAS. As smoltified fish prefer higher salinities, this requires the salinity to be changed from freshwater to saline water during the fish production cycle. Salinity variations can greatly inhibit the bioreactor’s performance, causing ammonia and/or nitrite accumulation in the RAS. As both these compounds are extremely toxic to fish, it is vital to maintain the nitrification performance during salinity changes.

The results are already being used by industry

My aim was to develop strategies to acclimate the bioreactor, so that salinity changes may be conducted safely for the fish. My Industrial PhD was established as a collaboration between Nofima, Krüger Kaldnes AS, and NTNU, and was a part of CtrlAQUA SFI – Centre for Research-Based Innovations in Closed-containment Aquaculture.

In my thesis, I investigate strategies that can improve the performance of bioreactors under varying salinities. More importantly, I propose several strategies that can be practically applied in industrial RAS to augment the bioreactor performance, and thereby, improve fish production and welfare. Many of the results are already being practically applied in commercial and semi-commercial RAS. While the strategies were motivated by the challenges in RAS, they can also be applied in the treatment of high or variable salinity effluents produced by other industries.

My research also provides a deeper insight into the microbial composition under salinity changes. As such, I hope that my findings will satisfy an audience interested in the engineering applications, as well as those curious about the microbes that can explain the science behind these applications.

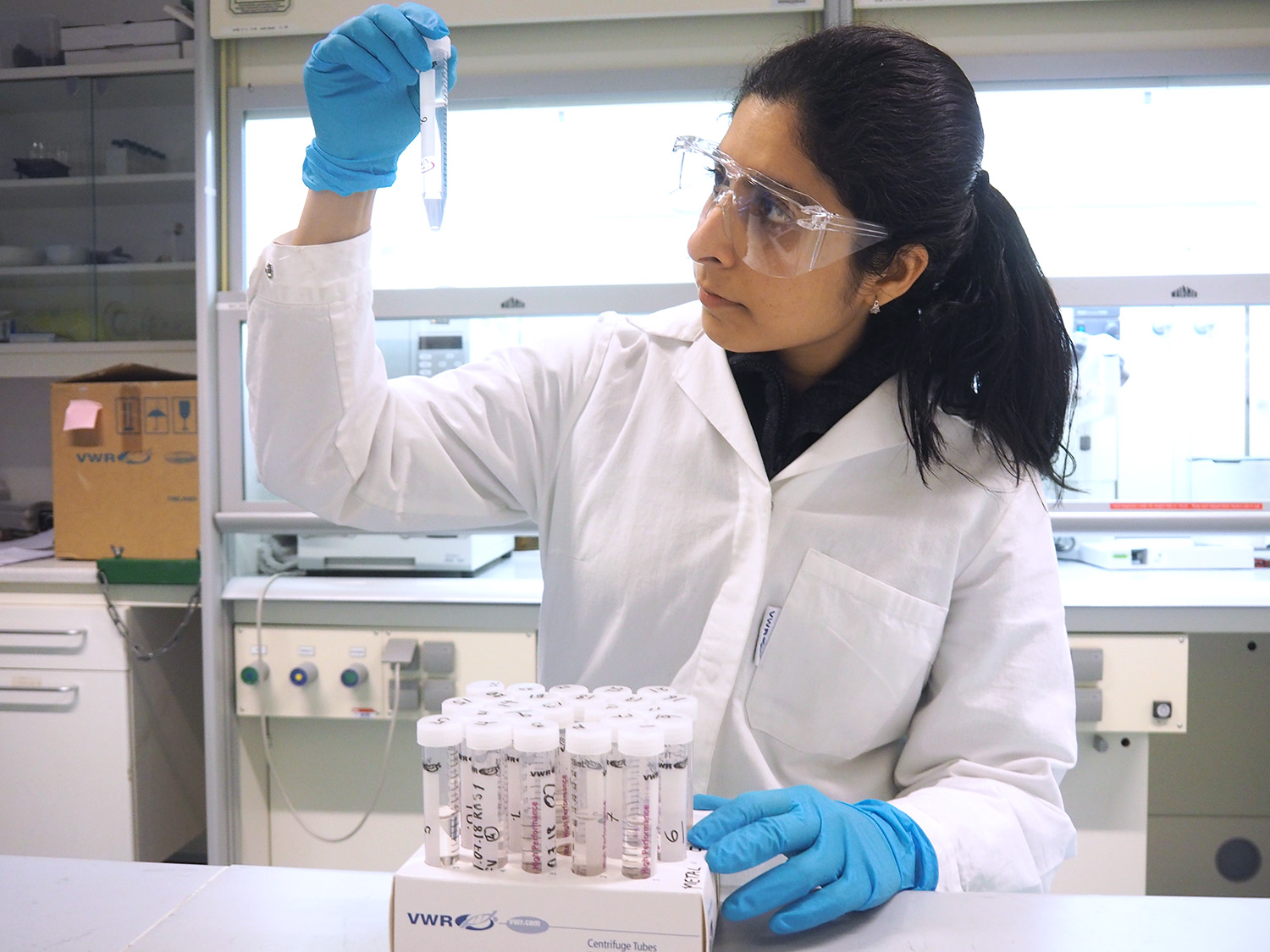

Sharada Navada

Sharada Navada was a PhD candidate at the Department of Chemistry at NTNU. She successfully defended her PhD theses in February, 2021. Her PhD dissertation was part of CtrlAQUA SFI, Research-Based Innovation in Closed-Containment Aquaculture – and also the result of a collaboration between Nofima, Krüger Kaldnes AS and NTNU.

Tags In

Search

Søk

Categories

- Arctic Research

- Arkitektur

- Bærekraft

- Bioingeniørfag

- Biologi

- Biology

- Biomedical Laboratory Science

- Biotechnology

- Bioteknologi

- Chemical Engineering

- Chemistry

- Climate

- Computer Science

- Datateknologi

- Digital

- Elektronikk

- Energi

- Energi

- Energy

- Engineering

- Engineering

- Environment

- Food Science

- Forskning

- Fysikk

- Fysikk

- Havbruk

- Informasjonsteknologi

- Informasjonsteknologi

- Ingeniørvitenskap

- Kjemi

- Kjemisk prosessteknologi

- Kjemisk prosessteknologi

- Kreftbehandling

- Kybernetikk

- Marine Technology

- Materialer

- Materials Science

- Materialteknologi

- Matvitenskap

- Meninger

- Miljø

- Min ph.d.

- My PhD

- My PhD

- My postdoc

- Nanotechnology

- Nanoteknologi

- Ocean

- Oil and gas

- Physics

- Research

- Simulering og visualisering

- Spør en forsker

- Studentliv

- Sustainability

- Ukategorisert

- Universitetsliv

- University Life

Kategorier

- Arctic Research

- Arkitektur

- Bærekraft

- Bioingeniørfag

- Biologi

- Biology

- Biomedical Laboratory Science

- Biotechnology

- Bioteknologi

- Chemical Engineering

- Chemistry

- Climate

- Computer Science

- Datateknologi

- Digital

- Elektronikk

- Energi

- Energi

- Energy

- Engineering

- Engineering

- Environment

- Food Science

- Forskning

- Fysikk

- Fysikk

- Havbruk

- Informasjonsteknologi

- Informasjonsteknologi

- Ingeniørvitenskap

- Kjemi

- Kjemisk prosessteknologi

- Kjemisk prosessteknologi

- Kreftbehandling

- Kybernetikk

- Marine Technology

- Materialer

- Materials Science

- Materialteknologi

- Matvitenskap

- Meninger

- Miljø

- Min ph.d.

- My PhD

- My PhD

- My postdoc

- Nanotechnology

- Nanoteknologi

- Ocean

- Oil and gas

- Physics

- Research

- Simulering og visualisering

- Spør en forsker

- Studentliv

- Sustainability

- Ukategorisert

- Universitetsliv

- University Life