Blue skies innovation

Basic research (or blue skies research) may be defined as research to understand the basic mechanisms of nature. Such research is often regarded as curiosity driven and defined by scientists.

Crack-detecting waves

Whether they transport oil, gas, water, or other substances – you do not want them to leak. But if a pipe is in an inaccessible area, how do you then check for cracks? And if there are any – are they critical, or not?

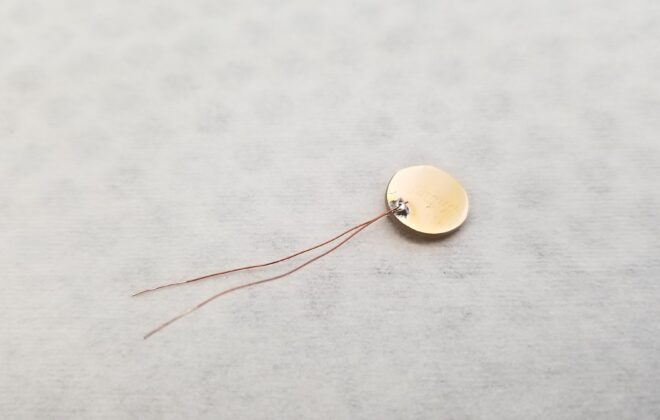

The heat is on – transducer design

To inspect and test oil pipelines is crucial – both for health and safety, and for the environment. But the harsh conditions mean specialised equipment is imperative. When using ultrasound to perform non-destructive testing, this translates into a need for transducers that can withstand extremely high temperatures.

Detecting the smallest leakages without delay

Leaks in oil & gas boreholes can have serious consequences. But current monitoring methods have a significant information delay and are not very sensitive. This is why we have developed a new method that eliminates delay, and which can detect the smallest leakages.

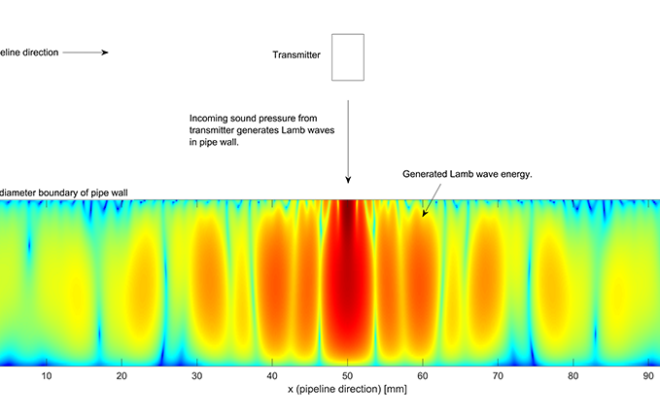

Ultrasound for improved crack detection

I have a created a modelling tool that can calculate ultrasonic sensitivity of cracks in pipelines, which is 8 times faster than commercial software. The model can simulate the behaviour and characteristics of waves within a pipe wall which are generated when an ultrasonic transmitter is radiating sound towards the pipe wall. These internal waves will be distorted somehow when encountering a crack, so knowing how these waves behave is vital in optimizing sensitivity in crack detection applications.

We built an AI tool to help avoid environmental disasters

Artificial intelligence helps us more and more with decision-making in fields such as medicine, transportation, and information retrieval. In collaboration with Equinor, Norway’s biggest oil and gas company, we have now added another field to the list: Interpreting integrity logs from oil and gas wells. Together, we built an AI-based assistant for Equinor’s log interpreters that they are now using in their daily work.

Aiming at lifelong partnerships in North America

Two CIUS-associated projects have received INTPART funding for collaborations with institutions in North America: NeoDoppler and blood speckle tracking (NTNU) with SickKids Hospital in Toronto, Canada, and two exchange agreements (USN) with Stanford University, CA, and the University of Washington, WA, USA.

Spring Conference 2022 – imaging in more ways than one

This year’s spring conference approached imaging from an academic, industrial – and artistic angle. Around 70 participants came to Grand Hotel Åsgårdstrand in Vestfold to share the latest on ultrasound developments in CIUS and ongoing research and development from our partners located in Horten.

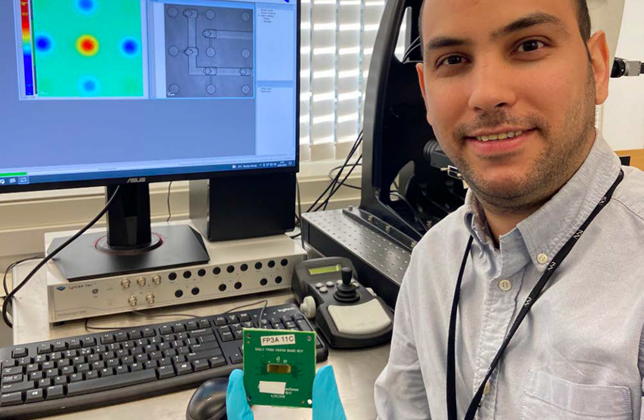

Ultrasound on a chip

“When you put something on a chip, you are democratising it because it is going to be cheaper and more accessible,” says Amirfereydoon Mansoori. His PhD work aims to contribute to that.

The biased inventor – when an innovation fails

As a researcher in CIUS my job is to develop new knowledge, concepts, and methods to further science and innovation. In doing so, it is easy to be misled, or biased if you will, by one’s own ideas. This is a true story.